Our Technology

Through our latest technology and careful research, Bidi Vapor has developed and improved the technology of the BIDI® Stick. Our efforts have resulted in an innovative vaping device that provides a premium experience. We use high-quality components, making them recyclable and long-lasting while giving smooth throat hits in one disposable vape pen.

What’s in a

BIDI® Stick?

Class A Nicotine

We use medical-grade (6%) from quality tobacco plants for the e-liquid to provide smooth throat hits.

280 mAh Long Lasting Battery

A high-quality cellphone-grade battery that is recyclable and heavy-duty, which can last until all the e-liquid is deployed.

Benzoic Acid

When combined with nicotine, benzoic acid vaporizes the e-liquid at lower temperatures.

Sensitivity Control System

Innovative technology with a sensitivity-sensor system ensures the user gets a consistent 6% nicotine in each draw. The pressure sensor will provide only the right amount of vapor relevant to a person’s lung capacity.

UL 8139 Certification

The UL 8139 standard is a battery safety standard for e-cigarettes. As a UL-certified product, the BIDI® Stick demonstrates Bidi Vapor’s commitment to providing high-quality products.

Medical-grade Absorption Pad

The high-quality pad in the BIDI® Stick has excellent absorption and heat resistance, ensuring a premium experience.

Propylene Glycol and Glycerin

Both propylene glycol and vegetable glycerin are liquid bases that produce thick clouds when exhaled.

Flavor Additives

The premium flavors of BIDI® Stick combine artificial and natural ingredients, delivering an unforgettable taste profile.

Completely Self-contained Disposable E-cigarette

To ensure product safety, we designed the BIDI® Stick to be tamper-resistant. This forward-thinking technology also hinders dubious usage after the BIDI® Stick is used up.

ISO 9001 & CGMP Certified

Bidi Vapor strictly complied with all manufacturing standards; from conceptualization to manufacturing, Bidi Vapor has obtained the necessary certificates to ensure a premium vaping experience.

Recyclability of the BIDI® Stick

01 / 11

Internal Fixation Base

It holds the heating coil assembly in place and acts as a

sealer to prevent

leakage of the e-liquid to the battery and

controller in the device.

Recyclability:

The device is made of food-grade silica gel and recylable to

more than 80%.

02 / 11

Fiberglass Tube A

It is a hollow tube with both ends

open. The small opening acts as a

pocket for the heating coil, while

the top end facilitates air supply

to the heating coil during vaping.

Fiberglass Tube B

It provides additional strength

to Fiberglass Tube A by covering

its open area. It also separates

the e-liquid and airflow channels.

Recyclability:

After the glass fiber tube is discarded, it needs to be recycled and

specially scrapped to avoid environmental pollution.

03 / 11

Oil Storage Cotton

It acts as a storage tank for the e-liquid.

It can also be used as a renewable energy source for thermal power generation.

Recyclability:

Its product recycling rate is more than 85%.

04 / 11

Heating Coil

The heating coil is made up of a coil gauge that is

nickel-chromium alloy sparkles and organic cotton. It

vaporizes the e-liquid into vapor during use.

Recyclability:

It has a recycling utilization rate of more than 90%.

05 / 11

Heat Shrinkable Tube

The shrinkable heat tube is an insulating bushing that

seals, insulates, is waterproof and dust-proof to prevent

short circuits.

Recyclability:

The heat shrinkable pipe recycling utilization rate reaches 60%.

06 / 11

Mouthpiece Cover

It seals the aluminum tube from the top and acts as a

mouthpiece for the device. This mouthpiece cover also

ensures a secured seal between the lips and the device.

Recyclability:

The mouthpiece cover can be recycled to more than 90%.

07 / 11

Mouthpiece Seal Pad

It acts as a sealer to prevent leakage of e-liquid from going

into the mouth.

Recyclability:

Made from food-grade silica gel, it can be recycled to more than 80%.

08 / 11

Controller Case

It is the protective body for the

controller and ensures that the

controller works properly.

Controller

It drives the battery and controls

the stable output of the battery voltage.

Recyclability:

The silica gel can be recycled

to more than 80%.

Recyclability:

Its product cycle utilization rate

reaches at 75%.

09 / 11

Aluminum Tube

It serves as the main body of the BIDI® Stick, where all

components get attached.

Recyclability:

Recycled aluminum can save 95% of the resources needed for new aluminum production.

10 / 11

Oil Absorption Cotton

This oil absorption cotton absorbs the condensation

droplets to prevent them from being inhaled into

the mouth.

Recyclability:

The product recycling rate exceeds 95%.

11 / 11

Bottom Cap

This seals the aluminium tube

to prevent the internal structure from

falling off. There is an intake hole at

the bottom that takes air in through

the bottom.

Bottom Case

This seals the bottom cap to prevent

leakage during transportation and

keeps the bottom case clean and

dust-free.

Recyclability:

The recycling rate of this material

is more than 90%.

Recyclability:

The silica gel can be recycled to

more than 80%.

R&D Patents

Science Behind Bidi

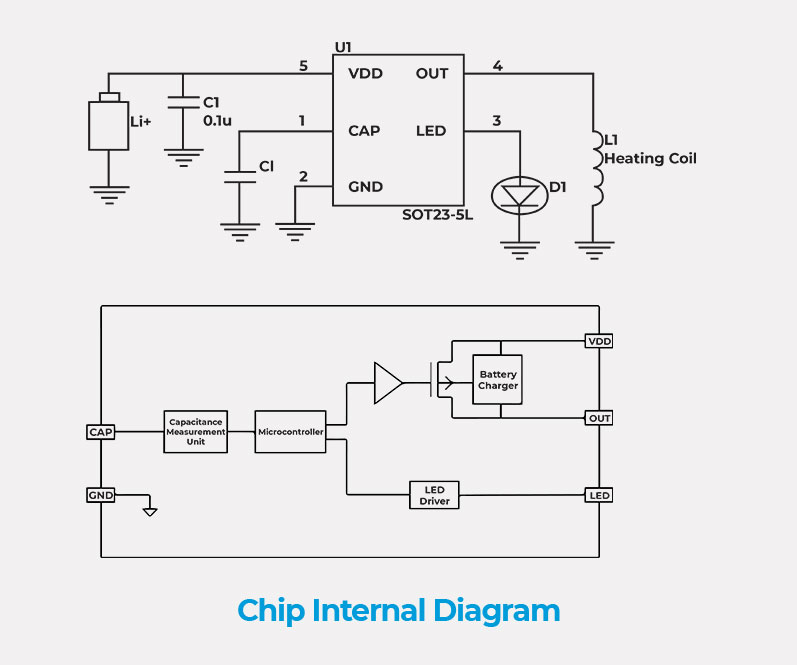

Microchip Drive Heating Technology

Main Advantages of the BIDI® Stick

The BIDI® Stick was designed and imbued with the latest technology to achieve and deliver a premium experience for adults aged 21 years and over.

Patented Mouthpiece

Technology

Sensitivity Control

System

Bidi Vapor has developed a unique sensitivity control system incorporated in each BIDI® Stick. This microchip sensitivity control system guarantees that consumers will experience consistent premium nicotine quality in every puff.

Consistent Nicotine

Delivery System

Management System

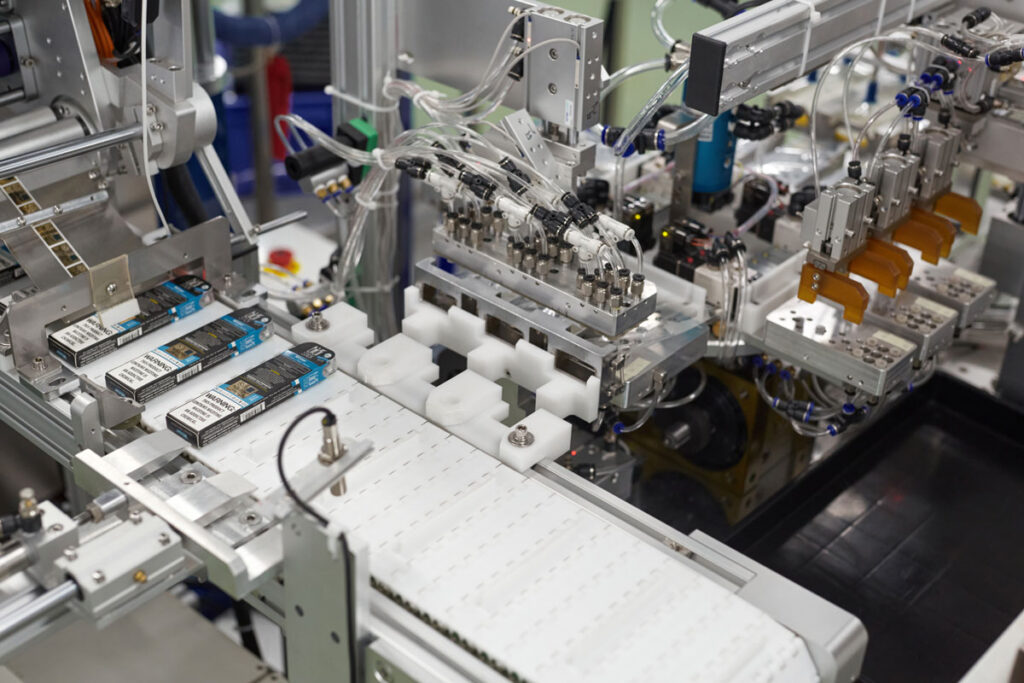

A robust quality system addresses the FDA’s goal of protecting the public to ensure that manufacturers provide consistently high-quality products to consumers.

During the company’s production and environmental processes, the Quality Center follows principles outlined in ISO9001:2015, cGMP QSR820, ISO14001:2015, ISO13485:2016, HACCP, and other quality and environmental system guidelines for quality control, and systematically manages product quality in accordance with the American Food and Drug Quality Management Code.

Heating Coil Technology

Heating Coil Technology

A robust quality system addresses the FDA’s goal of protecting the public to ensure that manufacturers provide consistently high-quality products to consumers.

The BIDI® Stick uses a nickel-chromium alloy crosswise with the organic cotton heating element. Nickel-chromium alloys have high strength and corrosion resistance. The alloy is composed of iron and nickel, which are commonly known as stainless steel materials. Nickel-chromium alloys have a longer life and a more stable overall performance.

Technical Advantage

Five professional perfumers, two 1000- level perfumery rooms, and three levels of automatic filling equipment will provide you with the solution of the e-liquid.

E-liquid Solution

Formulation and product development

Customized deployment

Marketing and branding assistance

E-liquid modulation

Taste optimization and improvement

Specifications and Tests

Complies with FDA requirements

Product testing services

Chemical analysis and testing

Professional Filling

Oil temperature control

Humidity control of oil reservoir

Temperature control of oil reservoir

Automatic filling equipment

Technical Advantage

E-liquid Solution

Formulation and product development

Customized deployment

Marketing and branding assistance

E-liquid modulation

Taste optimization and improvement

Specifications and Tests

Complies with FDA requirements

Product testing services

Chemical analysis and testing

Professional Filling

Oil temperature control

Humidity control of oil reservoir

Temperature control of oil reservoir

Automatic filling equipment